Besides the economic slowdown wrought by the COVID-19 pandemic, another issue that has raised concerns around the world is the security of the global food supply chain. This is especially significant for small countries like Singapore that rely heavily on food imports. As a result, recent border closures within the ASEAN region have made many worried about their daily food supplies being disrupted or made unavailable.

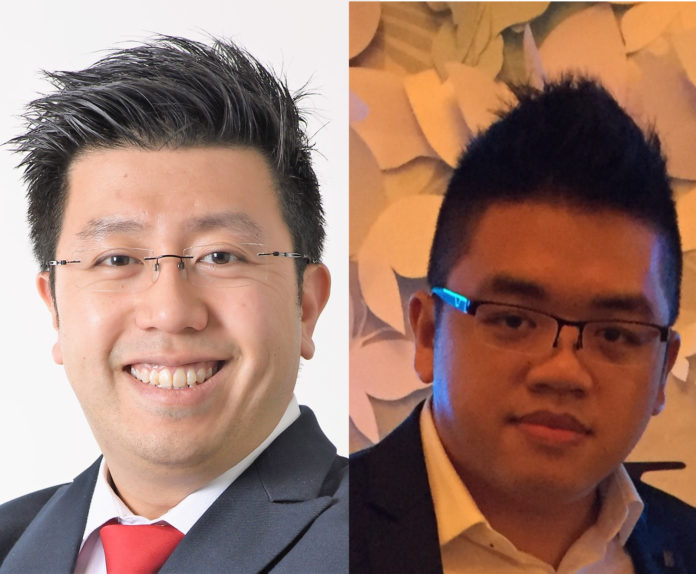

In our interview with Mark Tan, Sales Manager of Vismark Food Industries Pte Ltd & Eugene Tan, Head of Special Projects of Pere Ocean, SMEHorizon discusses the pre-emptive measures they’ve taken to keep Singapore fed in times of crisis, and how they continue these efforts during the current Circuit Breaker measures.

The importance of business continuity plans (BCP)

Both companies had BCP in place before the current situation, allowing them to enter this period prepared. Mark Tan shared how the experience of SARS in 2003 was very useful, and how Vismark Food Industries’ BCP readies manpower and vehicles to be activated to address a sudden surge in food demand. “When we heard about the news of COVID-19, we have already increased our stockpile,” he concluded.

Similarly, Pere Ocean’s BCP prepared them to face the stricter guidelines for social distancing now introduced. According to Eugene Tan, through the BCP the company could “reallocate the workforce into shift A and shift B formats for critical roles and WFH (work from home) for the less critical departments.” This involved readjusting work hours and the work week to give “minimal contact and interaction between employees”.

Apart from this, the business, which supplies to many key essential industries that are still up and running during this period, takes all measures to ensure that the staff are safe, including daily temperature taking, allowing for contactless drop offs and providing fresh masks to our drivers who come in contact with our customers. “This will lend a sense of assurance that their supplier has taking necessary measure to make sure everyone is safe,” said Eugene Tan.

Using technology to manage changes in demand

With international travel restrictions and social distancing measures in place, sales has been inevitably affected. Both companies rely on technology to address this. For example, Vismark Food Industries moved quickly to list their items on the e-commerce platform SGFoodMart.com, increasing sales and moving into another point of sale quickly.

Eugene Tan noted that “with COVID-19, we noticed a spike in recent orders, especially for homes, as many more are choosing to do their grocery shopping and getting their necessity online and delivered to them rather than making the physical trip to the store and sometimes get stuck in a queue.” This has proven to be an opportunity to entice local customers, and consequently the company has been redirecting more of its marketing budget to focus on their online presence and doing more online promotions to expand their outreach.

Addressing Singapore’s Food Security

Both companies regard Singapore’s food security as a critical issue, one that according to Eugene Tan has only been “accelerated and highlighted” by the COVID-19 pandemic. Sharing his company’s long term measures to ensure that Singapore remains fed, Mark Tan says that Vismark Food industries sources raw ingredients from different countries to reduce any sudden shortage or disruption.

“We do our own stockpile and ensure that customers’ orders are not affected for at least 6 months minimum. We support Singapore government’s initiative for taking Food Security as a priority and will continue to support the local farm,” he continued.

Eugene Tan also described working together with the government and its people “to make sure the supply line stays open even during difficult times”. He added that “our employees are also committed to this view. Besides diversifying some of our operations overseas, we predominately work with our own fleet of vehicles that ensures we are in absolute control of the delivery of products be it locally or imported,” he added

Other measures Pere Ocean has taken include ensuring ample warehouse space, that equipment is both efficient and environmentally friendly, and that manufacturing capacity is able to cope with any surge in demand. “All these are necessary when considering the long term food security of Singapore at hand,” says Eugene Tan.

Contributing to Singapore’s stability through Total Defence

Besides ensuring to Singapore’s food security, the companies also contribute towards total defence through their policies on employees with NS commitments. These include Vismark Food Industry’s “zero deferment policy for all our NSmen employees with In-Camp Trainings (ICTs)”, insistence that NSmen comply with IPPT obligations, and even encourage employees to extend NS service if possible.

Similarly, Pere Ocean provides support for mobilisation and IPPT duties, in recognition that skillsets acquired during their NS days would also value add to their work.

Shared Eugene Tan, “any testimonials and certificates issued by their unit will also be taken into consideration during the interview process. Whenever possible, we do encourage applicants to share about their NS experience as it helps us understand how they manage difficult situations they are placed in. Typically these experiences are unique to only those who have served their national service.”